Smart Fastening

Intelligent fastening solutions and critical joints to meet the needs and demands of sectors such as aeronautics, wind energy, mining and road infrastructure.

Discover the business View websiteIntelligent fastening solutions and critical joints to meet the needs and demands of sectors such as aeronautics, wind energy, mining and road infrastructure.

Discover the business View website

Services, solutions and products in the world of advanced bolted joints

The original bolting activity has evolved into sophisticated intelligent solutions for fastening and critical joints, to meet the needs and demands of sectors such as aeronautics, wind power, mining and road infrastructure.

ERREKA continues to work together with technologically disruptive companies to increase its value proposition.

Technology

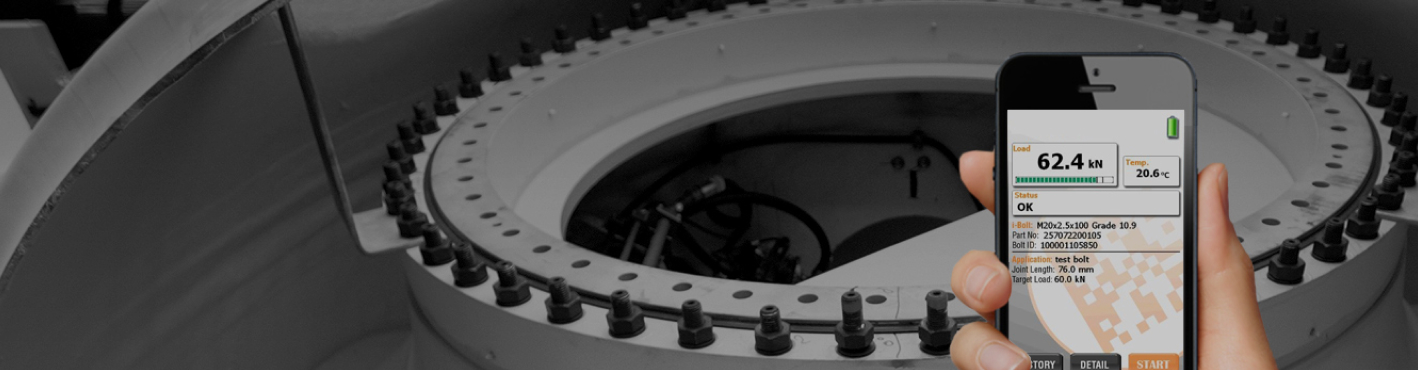

Digital Bolt®

Ultrasonic Technology for Fastening. Allows the bolted joint to be monitored throughout its working life through load inspections.

ERREKA offers solutions where the working structure is located in a hostile, remote and inaccessible environment. A clear example of this is the offshore environment, where offshore wind farms are installed. In this case, having a technology such as i-Bolt®, makes it possible to monitor the load of each bolt remotely, avoiding unnecessary displacements of the maintenance team, enabling predictive maintenance and controlling the evolution of the same when access is impossible.

Uptime and energy production are extremely important for the profitability of wind farms, hence the importance of ensuring operational excellence and the efficiency of ageing equipment.

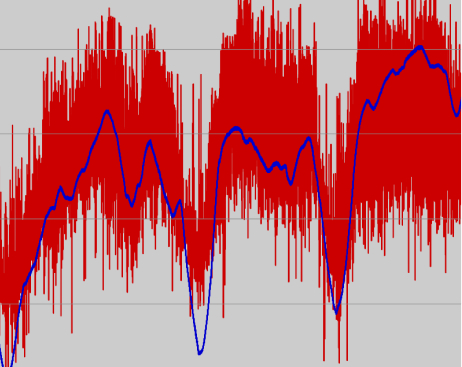

Another variable to be taken into account is wind force, which can also produce a deviation in the load and in the position of the blade. This results in a variation and dispersion of the load on the bolts. This event, apart from generating an additional maintenance cost, may reduce the service life of the joint, and even lead to accidents such as the blade falling. i-Bolt® technology and Erreka’s know-how can solve and avoid all these problems.

In the Oil & Gas sector, Erreka can also help avoid leaks from bolted joints, since being able to monitor the nominal load of each bolt in real time means the initial torque has a variation of ±3% with respect to the tension defined in the design. i-Bolt® not only avoids torque checks, but also reduces assembly and maintenance costs.

Did you know that…? 75 % of bolted joint failures are caused by inconsistent tightening.

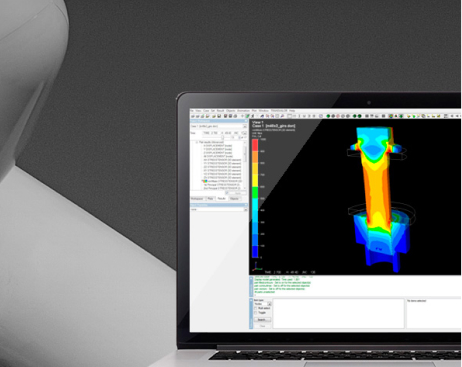

We have 60 years of experience in manufacturing and engineering bolts and screws with metrics greater than M80. We can diagnose, understand and predict the behavior of critical bolted joints in all types of conditions.

Nothing escapes us in the world of bolted joints. We develop innovative structures and bolted tools to carry out corrective operations and maintenance, so the customer saves the cost of using cranes. Our engineering and manufacturing team is ready to analyse our customers’ problems and produce customised ad hoc solutions.

We manage the entire life cycle of the bolted joint. While others focus solely on the installation process, Erreka covers everything from the conceptual design of the system through to management of its obsolescence, including data analysis.

We set ourselves apart from the competition thanks to our i-Bolt® solution, which allows direct load measurement using ultrasonic technology. The proven remote load monitoring system is unique, easy to install and universal, meaning it can be adapted to any operating system and type of management.

Providing solutions in the Oil & Gas sector.

Providing solutions in the Oil & Gas sector.

Robot working at ERREKA’s production plant in Antzuola, Spain.

Robot working at ERREKA’s production plant in Antzuola, Spain.

Contract manufacturing of polymer components for medical device and in vitro diagnostic test.